Managing water can be difficult, but finding the right partner can be easy.

With uncertainty surrounding increased environmental regulation in the coal-fired power industry, Veolia understands that water and wastewater management is essential in allowing you to keep up with power demand.

Experienced services and industry know-how

Effective water management operations play a crucial role in the power generation industry. Veolia is equipment agnostic and provides operations and maintenance services to any water and wastewater treatment system regardless of technology or manufacturer.

Our knowledgeable operators and supporting staff coupled with our years of experience and know-how allow us to meet your operation and maintenance needs in an efficient, cost-effective, and sustainable way.

Increasing output and reducing downtime

Veolia understands how to manage operational variables to increase reliability, uptime and business continuity, all things critical to power generation. We are experienced in increasing process efficiency and minimizing water usage including:

- Approach temperatures to increase efficiency and power generation

- Increase cycles of concentration while reducing water usage

- Recycling treated water from FGD systems

- Improving boiler efficiency with improved water quality and reduced blowdown requirements.

Enabling you to focus on your core business - power production

By outsourcing your water and wastewater treatment you are able to focus on your core power generation processes, while we take care of your water and wastewater challenges. Partnering with an experienced industry provider enables you to maintain predictable costs, offload a portion of the risk, and improve efficiency.

At a US coal-fired power plant, Veolia provided a Flue Gas Desulfurization (FGD) treatment system leveraging our CoLD® Process under an engineer, procure, operate or EPO agreement. Under this project delivery, Veolia guarantees: equipment schedule, process, long-term capacity, effluent quality and system availability. This includes full-risk maintenance for the process and ancillary equipment.

We collaborated with the customer to address challenges such as pH and TSS variations in the influent to ensure reliable treatment. The operations and maintenance (O&M) services began in 2019 after construction was complete and the project is considered a success by all parties. We are currently meeting all the performance requirements including providing high-quality effluent water for reuse.

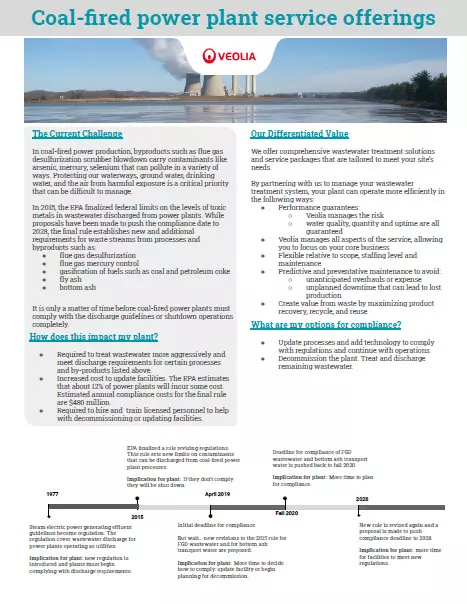

Learn how wastewater discharge can impact your plant and the measures you can take to be compliant.

Reducing environmental footprint for a more circular economy

Environmental compliance and sustainability are more important than ever for our customers. Veolia strives to be a partner in process innovation for customers looking to reduce their environmental impact. By re-imagining production processes, and repurposing by-products, your company can play a larger role in the circular economy.

Treating power plant wastewater for reuse or discharge can help:

- Extract value from material that might otherwise entirely be waste

- Reduce cost on input materials

- mitigate operational costs

- reduce the amount of wastewater you are sending to coal ash ponds

- Decrease the risk of leaks and groundwater contamination

- Reduce a plant’s carbon footprint

- Improve the overall efficacy of water management

With imminent EPA regulations on steam electric power generating effluent (40 CFR part 23) it is critical to manage the waste from coal-fired power generation like FGD, bottom ash transport, combustion residual leachate, in a safe and efficient manner. We are proud to deliver our operation and maintenance services in accordance with all applicable laws that govern water and wastewater treatment operations within the power industry.

"Coal ash is one of the largest types of industrial waste generated in the United States. Nearly 130 million tons of coal ash is generated each year."

Veolia provides operations and maintenance services to the power industry for the following essential processes.

Wastewater treatment

Leverage expertise and advanced technology to treat organic, inorganic, metals and total suspended or dissolved solids in wastewater.

Flue Gas Desulfurization (FGD) wastewater treatment

Keep your plant up-to-date and in compliance with EPA guidelines through proactive management of FGD wastewater. Treatment of wastewater creates volume reduction, increases the potential for water reuse, and minimizes the plant's overall environmental impact.

Gypsum Byproduct Management

Veolia can provide beneficial reuse options for the dewatered gypsum generated in the FGD process.

Stormwater runoff treatment

Ensure all effluent guidelines are met and reduce the risk of untreated water being discharged to local waterways by proactively treating storm runoff water.

Coal Ash Pond Water Treatment

Utilize expertise in operations to treat coal-ash (or “ash pond”) pond water for reuse within production processes or discharge to local waterways. Treatment of the wastewater reduces the chances of runoff and groundwater contamination.

Cooling water treatment and blowdown reuse

Protect against corrosion, minimize blowdown and increase the efficiency of operations by partnering with Veolia. Treating cooling tower blowdown or other waste streams for reuse as cooling tower makeup reduces total water demand for the plant and the amount of effluent needed to be discharged.

Boiler feedwater treatment and blowdown reuse

Prevent loss in production time due to impurities entering the boiler system that may cause increased fuel consumption, steam contamination and condenser corrosion. Demineralization pretreatment of the boiler water conserves the energy and water required, reduces the need for boiler blowdown, and enables higher boiler cycle rates.

Leachate and groundwater treatment

Reduce chances of landfill leachate and groundwater contamination. Treatment and reuse of this wastewater throughout power production processes help lower water usage rates.

Zero liquid discharge (ZLD) solutions

Remove all liquid waste from power plants' processes and treat wastewater for reuse. The ZLD treatment solution includes treating cooling tower blowdown, reverse osmosis (RO) reject, scrubber blowdown, landfill leachate, boiler blowdown, FGD purge and demineralization waste.

Providing safe solutions

When our team members are safe so are yours. Veolia's culture of safety is rooted in the philosophy that we are all obligated to protect one another. By instilling safety as a core value at every level of our organization, each employee commits to prioritizing safe behavior in everything we do. Working closely with our customers we adhere to their environmental, health and safety procedures.