Tackling Wastewater Challenges in Renewable Diesel Production

Mounting economic, social and regulatory pressures are driving alternatives to petroleum-based fuels. Renewable diesel has grown in popularity and can be produced as a 100% drop-in fuel within existing refinery hydrotreaters from vegetable oil, greases or animal fat feedstocks. However, the wastewater generated from renewable diesel production is of much higher biological strength and lower volume than traditional refinery wastewater, making it much harder to treat.

It all starts with pretreatment of feedstocks

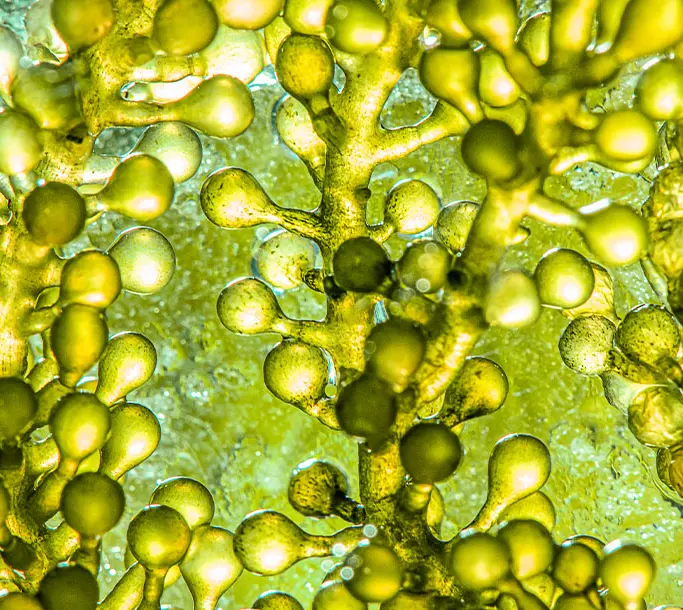

Pretreatment of renewable diesel feedstock is essential to reduce contaminants like trace metals, chlorides and phosphorus which can poison hydrotreating catalysts and corrode equipment. Most pretreatment systems use bleaching clay in a bleaching, degumming, filtration and deodorizing process. Feed pretreatment systems produce a wastewater stream that contains high levels of biological oxygen demand (BOD), chemical oxygen demand (COD) and fats, oils and greases (FOG), but also generates spent bleaching clay or silica which must be regularly disposed of. The conversion process produces a water condensate that is high in CO2/carbonates with sulfur (H2S) and ammonia and requires stripping to remove these contaminants. The combined wastewater is either treated onsite or in a downstream publicly-owned treatment works (POTW) facility.

End-to-end treatment with peace of mind

We can provide an end-to-end residual oil and waste-to-energy treatment process through a design-build-own-operate-maintain (DBOOM) with financing business model. We also provide performance guarantees to ensure satisfaction. Let our expert operators provide reliable and cost-effective wastewater treatment for your refinery so you can focus on the renewable diesel conversion process.

Insights

Biodiesel vs Renewable Diesel: Are They the Same? [view our blog post]

Energy Transition Deep Dive: Top 6 Challenges Renewable Diesel Producers Face [view our blog post]

How Do Renewable Fuels Fit Into the Energy Transition? [view our blog post]

Related Solutions

Converting Challenging Waste Streams into Valuable Products

Recovered residual oils from spent bleaching clay may enhance plant yield by 1 to 1.5% in renewable diesel production. The combined wastewater and degum centrate waste can be anaerobically digested to generate biogas, which can be cleaned and sold into the natural gas network as renewable natural gas (RNG). The RNG can be reused either with renewable energy or within steam methane reformers to generate supplemental hydrogen for the deoxygenation stage of the renewable diesel process. The renewable nature of RNG allows for a negative Carbon Intensity (CI) score, potentially qualifying the refinery for significant Renewable Fuel Standard subsidies and reducing the site's carbon footprint by up to 80%. This solution may also be applicable in the biodiesel and bioethanol industries which use identical organic feedstock pretreatment processes.

Related solutions

Veolia offers a number of additional technologies to support the production of renewable diesel. Comprehensive chemical programs to optimize renewable diesel processes include fuel additives (lubricity, cold flow and conductivity improvers), anti-foulants, deposit, microbial and corrosion control chemistries, and salt dispersants. Technologies include digestion and biogas cleaning through our proprietary anaerobic treatment processes.

Contact a representative to learn how Veolia can help you monetize your renewable diesel waste and wastewater streams.