The Opportunity in Municipal Wastewater Treatment

In the United States, the vast majority of wastewater treatment facilities are not being used to their full potential. Their local communities are missing out on major opportunities for economic development and revenue generation, green jobs and education, digital innovation, enhanced biodiversity, clean energy, resource circularity and climate resilience.

Currently in the United States:

of clean effluent is simply discharged

of biosolids are simply landfilled or incinerated

of WWTPs simply flare their biogas

What is a Veolia Ecofactory?

Ecofactory is a new way to think of your municipal wastewater treatment plant. It transforms what was once a traditional and linear treatment utility into a producer of sustainable resources and green energy, generating positive environmental impact, profitability and resilience, and a circular economy in your community.

How does a Veolia Ecofactory work?

Becoming an Ecofactory is a journey towards sustainability. Your municipal wastewater treatment plant can embark on this path by committing to various initiatives that promote efficiency, resource recovery and environmental stewardship. You may adopt these initiatives at different paces, focusing first on areas most relevant to your facility. Veolia will guide you through this transformation, helping you leverage your WWTP's potential to maximize economic and environmental benefits with a positive impact on the local community.

Download the infographic below to learn more

The Journey to a Veolia Ecofactory

Green Energy and Efficiency

Through energy efficiency, proactive maintenance and advanced processes for energy generation and storage, the Ecofactory not only creates sustainable green energy, but can export any excess to the community.

- Energy efficiency upgrades

- Facility maintenance and equipment optimization

- Waste energy recovery / Anaerobic digestion / Biogas generation

- Organic waste codigestion

- Renewable energy generation

- Energy storage

Water Reuse and Recycling

The clean, treated water byproduct from the Ecofactory is reclaimed for reuse, for groundwater recharge, or for the creation of saltwater intrusion barriers.

- Preservation of precious water resources

- Effluent reused for agricultural or urban irrigation

- Recharge groundwater reserves

- Support the stability of local ecology

Resource Recovery

Ecofactories recover valuable nutrients from the wastewater treatment process, minimize the solid waste they landfill, and create local beneficial use opportunities.

- Recover value from what was once considered waste

- Minimize landfill

- Support a sustainable, local and circular economy

Decarbonization

Greenhouse gas emissions, especially fugitive emissions from inefficient practices, are minimized by the Ecofactory, helping to mitigate climate change and improve local air quality.

- Electrification of vehicle fleets

- Stormwater is sustainably managed by green infrastructure

- Resources are recovered to avoid emissions that would occur outside the Ecofactory

Community and Environmental Stewardship

Green jobs and education opportunities are created for your community. Ecofactories also support local biodiversity and the surrounding natural environment, while maximizing their own climate resiliency.

- Workforce initiatives like Veolia Academy

- Community tours and educational workshops

- Biodiversity enhancement initiatives

- Investment in infrastructure enhancements to bolster climate resilience

The Wastewater Treatment Industry Has

Incredible Potential for Sustainability

Get Inspired Below

Danbury, CT

In Danbury, CT, a combined heat and power plant will use digester gas produced on-site to generate electricity and capture heat for various processes. Utilizing renewable energy sources such as biogas cogeneration and solar will reduce the plant’s carbon footprint. Soon, the first-of-its-kind facility will convert food grease into biodiesel, turning what used to be a financial burden into revenue. The construction and operation of the enhanced Water Pollution Control Plant will create green job opportunities for the local workforce.

Nassau County, NY

In Nassau County, NY, the water reclamation facilities reuse their effluent on-site, saving 360 million gallons of groundwater annually. Centrifuges dewater sludge, reducing the volumes to haul away and the associated transportation carbon footprint. A Biological Nutrient Removal system reduced nitrogen discharge into Back Bays by 40%, preserving marine life. For Earth week, the South Shore facility gave students tours and hands-on experiences about environmental protection

New Orleans, LA

In New Orleans, LA, the replacement of vaporizers with automated units will reduce annual electrical and oxygen usage.

Rialto, CA

In Rialto, CA, a pioneer microgrid project powered by biogas cogeneration, solar, and battery storage will provide energy independence, resilience, and efficiency to the wastewater plant. The facility provides tours, activities like building mini-aquifers, and $2,500 scholarships to inspire environmental stewards and serve the community.

West Basin, CA

In West Basin, CA, the water recycling facility treats 62 million gallons of wastewater daily for groundwater replenishment, commercial, industrial, and irrigation uses.

Honolulu, HI

In Honolulu, HI, the Honouliuli facility produces 12 million gallons of reclaimed water daily for industrial and irrigation purposes.

Holyoke, MA

In Holyoke, MA, the facility strengthens community ties through site tours, career fairs, medical donations, and river cleanup volunteering.

Fulton County, GA

In Fulton County, GA, membrane bioreactors will treat wastewater to cleaner standards than the receiving river, protecting downstream communities.

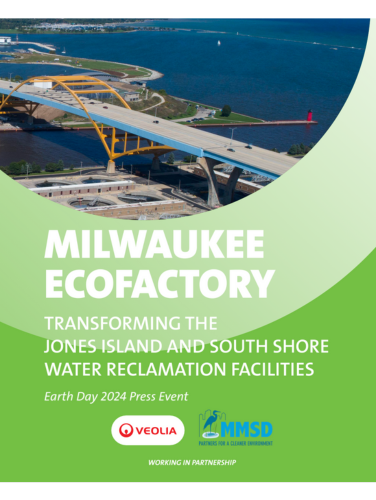

Milwaukee Ecofactory

Transforming the Jones Island and South Shore Water Reclamation Facilities

Milwaukee and the Milwaukee Metropolitan Sewerage District (MMSD) are already leaders in treating wastewater as a resource.

- Produces MilorganiteⓇ fertilizer, keeping more than 5 million tons of waste from landfills, as well as untold thousands of tons of fugitive landfill methane.

- Generates its own power and heat from biogenic anaerobic digester gas and landfill gas

- Co-digests high-strength wastes to divert them from landfills

- Plans to deploy solar PV, wind power, battery storage and/or waste heat recovery systems to achieve its goal of 100 percent renewable energy and a 90% reduction in its carbon footprint by 2035

- Reuses its treated clean effluent for on-site cooling water and cleaning purposes, avoiding the associated energy consumption and greenhouse gas emissions

- Champions biodiversity, undertaking pro-pollinator and anti-pesticide campaigns, providing a home for the widely-beloved nest box installation for the protected peregrine falcons that live on-site

- Partners to restore local wetlands and natural habitats and to reforest and clean up the greater Milwaukee River waterways

- Stormwater management and green infrastructure practices have mitigated over 145 billion gallons of combined sewer pollution from entering Lake Michigan.

MMSD and Veolia remain integral members of the local community, from hosting thousands of visitors annually, to committing to purchasing goods and services from small women- and minority-owned businesses and enterprises. Together, MMSD and Veolia aim to deliver public educational programming to increase local support and understanding of the District's operations and goals. Collectively each year, the workforce training programs run by MMSD and Veolia offer over 40 paid internship opportunities seasonally for local students and residents.

Veolia's Partnership Approach

Ecofactories should be addressed through a long-term partnership, where the benefits of incremental improvements can be realized over time without disruption to existing operations.

Not every wastewater treatment plant in North America is readily positioned to achieve all five pillars of Veolia’s Ecofactory concept.

Leverage Veolia's unique expertise at the nexus of water, waste, and energy to craft a tailored plan for your community's sustainable future.

A Proven Track Record

municipal water & wastewater systems operated across the U.S.

gallons of water saved for clients worldwide

tons of carbon emissions avoided for clients worldwide

Want to speak with someone? Contact us below: